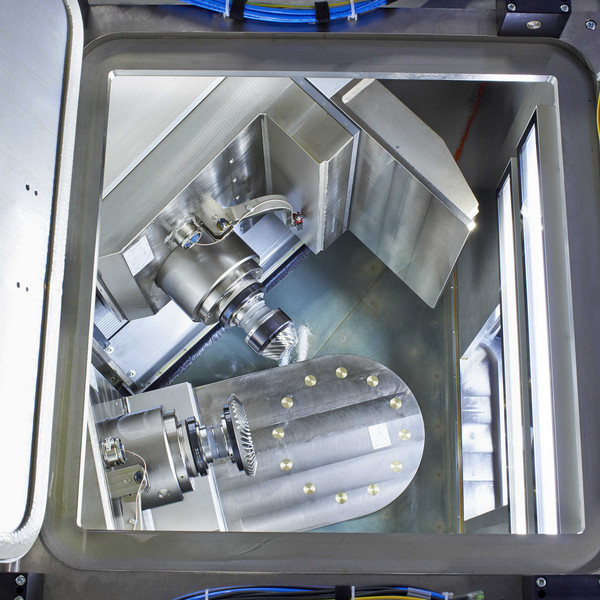

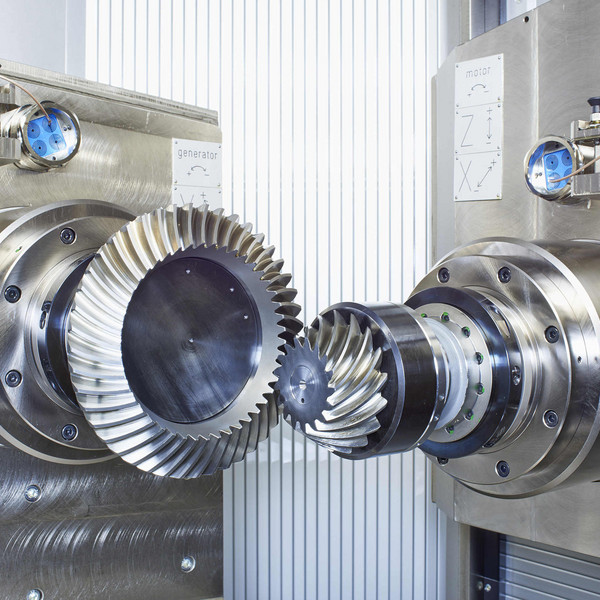

Bevel gear test rig TS-30

The bevel gear test rig allows testing of bevel gear sets of different sizes for wear and fatigue strength. Electric drives initiate the rotary motion (motor) at the drive side and the braking torque at the output side (generator). This concept permits running the test rig in a very energy-efficient way. The center distances and the shaft angle between the bevel gears can be individually set by means of the control. During the test run the speed, the torque, the vibrations, the oil pressure, the oil flow rate and the

temperature are continuously recorded and evaluated by the system control. The test runs can be individually programmed at the HMI. The workpiece holders are equipped with a telemetry system (DMS application) for measuring the torque and the tooth root bending directly at the test specimen. The position and the high accuracy of the DMS measuring system also permit calculation of the efficiency level.

Highlights and tests

- Programmable test rig

- Variable rotational speed and torque

- Variable setting of shaft angle and center distances

- Scuffing and pitting detection

- Efficiency level measurement

- Oil lubrication and oil heating

- High energy efficiency

- Vibration-damping basic body

Technical data and equipment

- Output: 2 x 156 kW

- Speed: 0 – 12,000 rpm

- Torque 1: 400 Nm at 1,000 – 4,500 rpm

- Torque 2: 100 Nm at 12,000

Please note: Performance data can be adjusted to the respective requirements.