Automation Solutions for electronics

With their customized scalability and the opportunities they provide for diversification, our machines and lines can offer the decisive head start in a competitive market. Strama-MPS is your manufacturer for assembly and testing machines for high-quality electronical components such as:

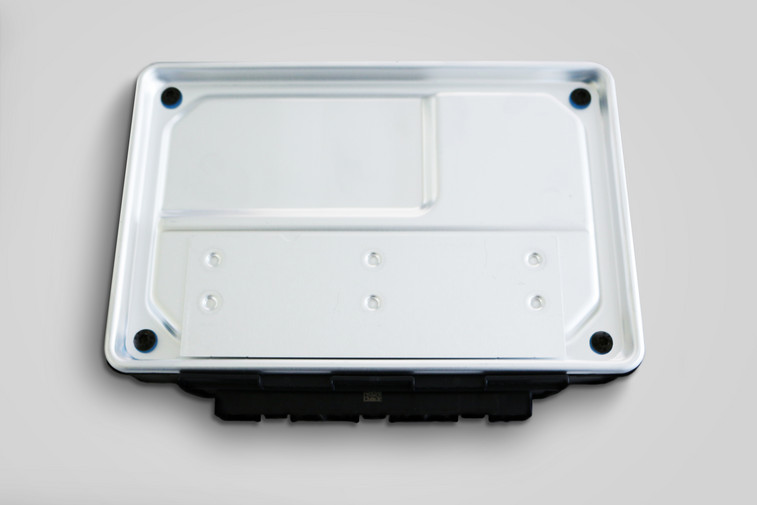

Control units

Control units in vehicles are becoming increasingly important. Autonomous driving is one of THE projects of the future - which means that the number of built-in control units will continue to increase constantly. Amongst others, the following standard processes are required for the assembly of control units:

- Press-fitting (force-path monitored with puncture test)

- Pin-check by means of image-processing

- Welding

- Leakage testing

- Connect for EOL and other function checks

- Laser marking

Leave it to the experts at Strama-MPS to integrate all these process (and others, as required) harmoniously into a line concept which is tailor-made for your requirements.

Navigation system

The use of entertainment, information and communication systems in vehicles gains more importance every day and the products concerned are subject to a rapid development. Our assembly and testing machines for navigation systems are well prepared for this development. The machines consist of several manual workstations as well as various automatic stations which are shunted to the main conveyor. New stations can easily and quickly be integrated. The machines allows for the handling of up to 100 component types.

Gateway

The machine assembles gateways for the automotive industry. The gateway distributes data securely between all bus systems and the outer world. The gateway ensures safe data distribution required for the communication within the vehicle and also features a communication interface for connecting to the word outside. Due to the access to data, sensors and actors within the whole vehicle, the gateway is able to host the upcoming vehicle functions and connected services.

PLC

Each machine or line is different with regard to its system performance and complexity as well as with regard to the demands on technology and safety engineering. This is why a multitude of controllers is required in order to allow us to develop the one and perfect control solution for each of your applications. The modular design of our assembly and testing machine allows for it to be easily and quickly extended so that we can ensure maximum flexibility as required by our customers. The machine allows you to produce more than 50 different component types. Loading and unloading of parts is done fully automatically. The assembly and testing machine combines a multitude of processes such as blank separation, laser marking, HV check, EOL check and inline check at an accuracy of 100%. With our easily exchangeable test adapters which feature more than 100 test channels we are able to offer another special highlight to our customers.

Throttle valve

Our semi-automatic assembly machine for throttle valve manufacturers focuses on the lean concept. This is why the line is designed in a U-shape thus allowing for external component logistics (at the rear of the line). Both the plastic laser welding of contour areas by segments with three optics, as well as the hot stamping of plastic pins are highlights of the line. The quality of the parts is tested by means of an air mass flow rate test using a laminar flow system.

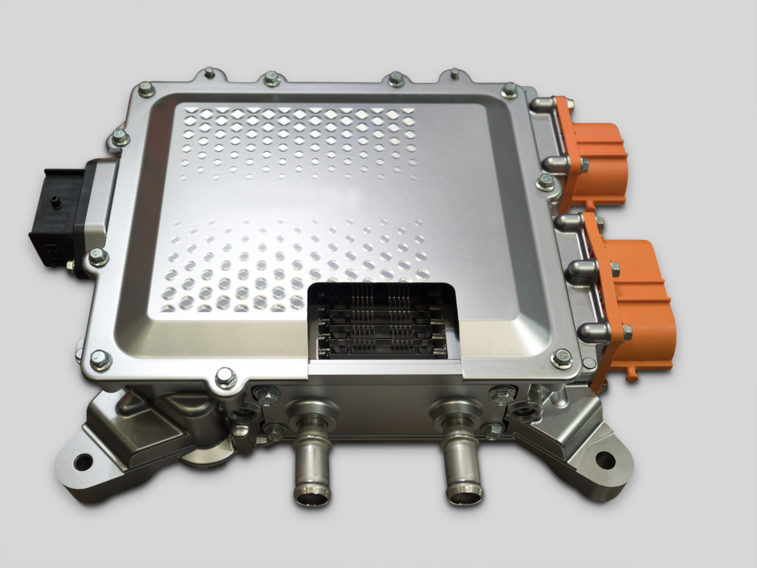

Power electronics

New and sustainable drive technology products in various mobility sectors result in new as well as challenging tasks for their automation, assembly and testing. To be able to react to the volatility of the market, intelligent, scalable and flexible concept solutions are required which meet the highest automation / assembly and test standards.

Based on a broad process and automation knowledge of electronic, electrical and mechatronic products we offer reliable and highly efficient solutions in the sector of power electronic assembly. The standardized Strama-MPS technology platform ProMoCell is the basis for scalability and flexibility. Our Strama LineDataServer is recording all machine and operating data and is the interface to your Manufacturing Execution System (MES).