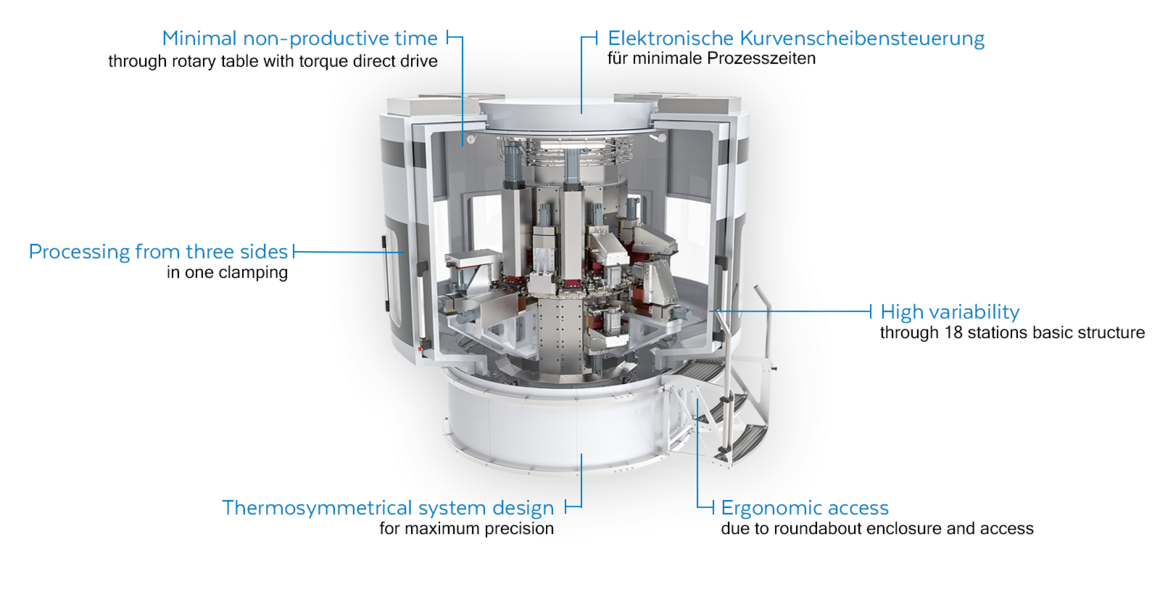

RT E-CAM

The fastest rotary transfer machine in the machining world

How can maximum productivity and flexibility be combined in one system concept?

By combining solid mechanics with electronic and variable cam disc control.

The RT E-CAM combines a wide range of customised machining options with one of the fastest rotary transfer machining centres in the world, setting new standards in the high-volume machining of precise small parts.

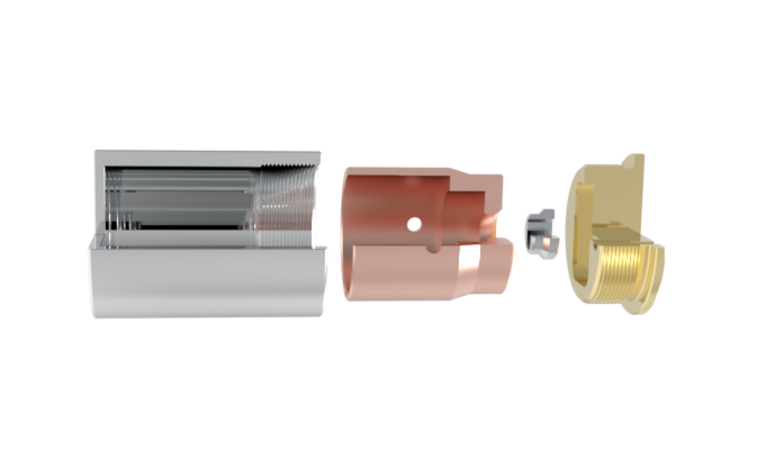

Component range

The RT E-Cam is designed for components with an edge length of 5 to 35 mm or a diameter of 5 to 35 mm.

The main areas of application are the machining of precise small components for electrical engineering, high-frequency technology, the automotive industry and the locking system industry.

Electronic cam disc control

The RT E-Cam is capable of mapping a mechanical cam disc using software and thus enables a highly flexible arrangement of a wide variety of machining processes.

The cams are calculated automatically, thereby realising the shortest process times with maximum variability.

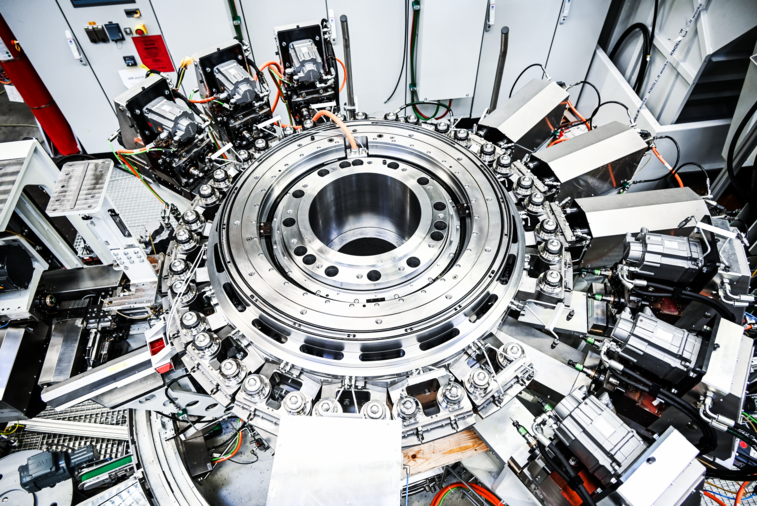

Rotary table

The heart of the RT E-Cam is our directly driven torque rotary table, which transports up to 18 clamping units from one process station to the next in under 0.25 seconds.

By using a high-precision absolute angle measuring system in conjunction with a maximally rigid bearing concept, a positioning accuracy of ±3µm can be realised even without Hirth gearing.

Direct request

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/0/csm_elektronischekurvenscheibe_grafik_01_35cbeba386.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/a/csm_Muehlbauer_Thomas_Neu_2024_805a71e4da.png)