Technology Services

Internet of Things (IoT), Artificial Intelligence (AI), Virtual Reality (VR), Cloud Computing, etc. are only some buzzwords to be heard daily in the media under the general term digital transformation. But what does that mean for companies in reality? What economic benefits can be generated in detail? How does these new technologies find a sustainable application in our daily life?

Digital solutions for proven Strama-MPS technology

To develop promising, economical and sustainable solutions for the mechanical and plant engineering industry on the basis of these new potentials, the Strama Group established an organizational unit with highly qualified, interdisciplinary and agile working teams, essentially concentrating on the mechanical engineering world of tomorrow. The so-called Technology Unit (TU) of the Strama Group was fixedly integrated into the global organizational structure. A central aim is to further expand and consolidate the Strama Group as an innovative and future-oriented partner for our customers.

A consistent and efficient digitalization strategy will be a key element for every promising company. Besides the necessary technical developments in the mechanical and plant engineering industry, the Technology Unit also focuses on the company structures of tomorrow resulting from the digital transformation. With our holistic and comprehensive approach (technology/innovation, organization, people) we want to stand out from our competitors and play an important role for our partners in the course of the fourth industrial revolution. True to our motto: MOVING THE LIMITS. TOGETHER. CONSTANTLY.

Expert services of our Technology Unit

In the Technology Unit of the Strama Group there are a number of technical experts whose services are also offered externally to customers and partners, tailored to meet your individual needs:

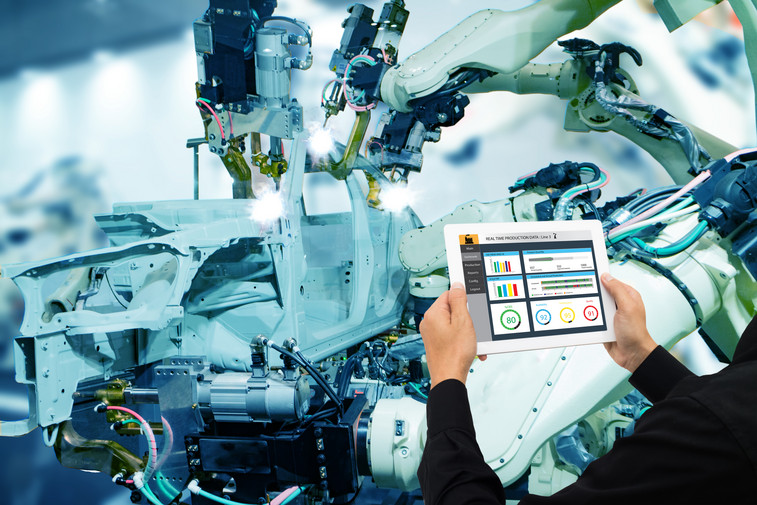

Industrial Internet of Things (IIoT)

In order to provide economical and flexible solutions to our customers as regards the Industrial Internet of Things (IIoT), the Technology Unit of the Strama Group has developed a SMART solution with the so-called Strama LineDataServer combined with the Frontend StramaAnywhere. These applications are designed primarily to provide a production line with maximum process transparency about the large amount of data gathered. Furthermore we are striving for continuous technical upgrading of the systems, so that on the basis of artificial intelligences (AIs) Predictive Maintenance as well as Machine Learning approaches can be economically integrated into a production environment and to create added value for our customers. We do not only provide services for newly developed equipment, but based on the enormous flexibility of the systems, we are also a strong partner in networking and digitalization of existing equipment.

Research & Development

We support you during your initial research ideas and with our expertise in the automation and digitalization sector we can be a strong partner. Thanks to our widely ramified network with universities, technical colleges and institutions we are an efficient link between the research and the industrial implementation of your idea for the future.